Robotics FSTP funding, beneficial for SME’s? – TRINITY experiences

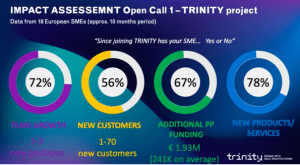

This workshop focused on FSTP funding for robotics projects from the point of view of the participating SMEs. Following the launch of Trinity’s open call for 18 European SMEs, 72% of participating organisations report team growth, 56% say that they have gained new customers and 76% of participating companies were able to attract additional funding, averaging 240 000 EUR per company. Lastly, the exposure and the additional funding has allowed the SMEs to launch new products or services.

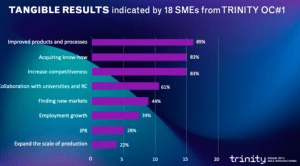

The impact of Trinity’s open calls resulted in equity-free funding expansion, sharing of the know-how of Trinity, increased mentorship opportunities and activity promotion.

Trinity speaker Mina Lanz also overviews the challenges when trying to attract new FSTP open call participants, stating that the number one reason for not participating is the lack of experience in international project collaboration as well as weak networks, followed by the lack of rudimentary stage skills. These challenges present opportunities for the robotics community, exposing the areas of improvement when trying to attract new projects. Firstly, the robotics network should be more open to less known projects, encouraging everyone to feel welcome in the community even when the AI does not have previous exposure. An open-minded and idea-driven approach should be promoted across the robotics community from both the funders and the SMEs. In light of this, Trinity is taking initiatives to implement more targeted and desirable services for SMEs. Trinity provides a list of recommendations for Digital innovation hubs wishing to attract more SMEs. DIHs are advised to create digital training solutions, create knowledge-sharing systems, promote inter-company networking and collaboration as well as provide cybersecurity services, testing facilities and advertising platforms for the projects.

Robotic solution for accurate grinding of complex parts

ALDAKIN showcases how Trinity provided them with the experience and networking opportunities needed to succeed in commercialising their robotic solution. With the help of Trinity, ALDAKIN was able to perform a diligent consumer needs analysis and perfect their robot prototype to stand out in the industry. The robotic solution for accurate grinding of complex metal parts includes the tool wear control for homogenous material removal, a human-machine interface and grinding strategy management as well as steady online robot and process monitoring. The biggest technical challenges in creating the solution surfaced while first dealing with automatic safety controls, particularly regarding the safe collision-free toll changing and calibration. Following the needs of operators, the creators developed a simulation of the real physics environment of the tool and the working process, which could not be considered by the CAM software due to the tool’s compliance.

Trinity funding allowed ALDAKIN team to collaborate with Moduleworks, one of the global leaders in simulation software development, and to devise solutions for enhancing the CAM software to fit their solution’s needs. Using the expertise of field professionals and researchers allowed the creators to widen their knowledge and respond to the challenges with confidence in turn improving their product.

The next negation of the Human-Robot interface

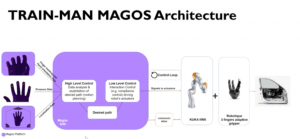

Magos demonstration is yet another example of a successful funding initiative at Trinity. Magos creator Greg Agriopolous presents their product TRAINMAN MAGOS, the next negation of the Human-Robot interface. TRAINMAN seeks to enable new automated solutions for industrial robots, offering increased dexterity through human-centric robot programming procedures. Magos gloves act like a robot training tool, teaching robots human-like motion and precision through tracking operators hand movement while wearing smart gloves. The data on movement allows rapid training through tracking and transferring correct task performance data into the robotic system preferences, working with systems like KUKA, IIWA and ROBOTIQUE gripper. The gloves are integrated with finger tracking, hand orientation tracking, 3D localisation and haptic feedback sensors. Magos gloves offer the highest precision of finger tracking across all similar products on the market.

The data from the gloves is then sent to a computer where it’s analyses through a series of algorithms selecting the appropriate robot model and control preferences. The results are then re-checked and controlled with corrective actions. The system learns the task trajectories directly from the human operator and was tested on complicated tasks like picking up a glass and placing it in a special compartment, showing high accuracy. System training with Magos saves up to 20% of programming time.

Trinity investment has not only allowed Magos to validate the product at TRL 6 but also led to obtaining the resources to perfect the industrial design and move to TRL 7. Furthermore, financing has allowed Magos to get in touch with high profile clients ready to implement the product in the working environment.

Funding opportunities from Trinity were vital for the project’s success, allowing SME’s to address project challenges with necessary support and resources, this way reaching the full potential of their ideas, all while expanding professional robotics community networks.

Our community of EU robotics projects improves collaboration between European robotics DIHs with a mission to strengthen the competitiveness of the European robotics market. We represent 5 innovation actions from 4 application areas: DIH HERO (healthcare), RIMA (infrastructure inspection and maintenance), agROBOfood (agri-food), TRINITY and DIH2 (agile production). Discover how RI4EU can spur your innovation and support your digital transformation – follow RI4EU on LinkedIn and Twitter and subscribe to our newsletter.